Hygiene Station for 60 Employees Workshop: A Comprehensive Solution by WONE

In the food processing industry, maintaining impeccable hygiene is not just a regulatory requirement—it's a moral obligation. Contamination

risks, cross-contamination via footwear or hands, and inadequate sanitation practices can lead to product recalls, reputational damage, and

even public health crises.

For food workshops employing 60 workers, the challenge of ensuring consistent hygiene across all personnel is magnified. Traditional setu-

ps, such as separate handwashing sinks, boot scrubbers, and sanitizing stations, often occupy excessive space, create workflow bottlenec-

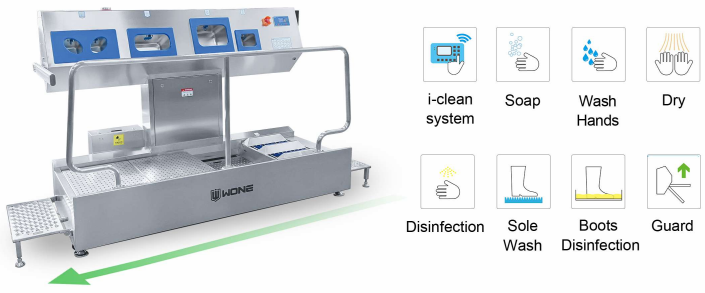

ks, and fail to meet the demands of medium-to-large teams. Enter the PBW-25 Hygiene Station by WONE—a compact, multifunctional solu-

tion designed to streamline hygiene protocols for food plants while accommodating up to 60 employees efficiently.

The Hygiene Challenge in Food Workshops

Food processing facilities are high-traffic environments where employees move between raw material handling, processing, packaging, and

storage zones. Each transition poses a contamination risk if proper hygiene isn’t enforced. For a team of 60, the limitations of conventional

hygiene equipment for the food industry become apparent:

- Space Constraints: Multiple stations for handwashing, drying, and boot cleaning clutter workspaces.

- Time Inefficiency: Employees waste time moving between disjointed stations.

- Compliance Gaps: Inconsistent adherence to protocols increases audit risks.

- Resource Waste: Excessive water, energy, and disinfectant use drive up costs.

The PBW-25 addresses these challenges by integrating five critical functions into a single unit: hand washing, hand drying, hand disinfec-

tion, boot cleaning, and boot disinfection. This innovation not only conserves space but also ensures compliance, efficiency, and scalability.

Introducing the PBW-25: A Compact Powerhouse for Food Plant Hygiene

WONE, a leading hygiene station manufacturer, engineered the PBW-25 to meet the rigorous demands of food workshops. Its design reflec-

ts decades of expertise in creating hygiene equipment for the food industry, combining practicality with cutting-edge technology.

Key Features of the PBW-25 Hygiene Station

- Multifunctional Design

- Hand Washing: Touchless sensors dispense antibacterial soap and water at optimal temperatures.

-

.png)

- Hand Drying: High-speed air dryers reduce moisture, minimizing bacterial growth.

-

- Hand Disinfection: Automated dispensers apply food-safe sanitizers.

-

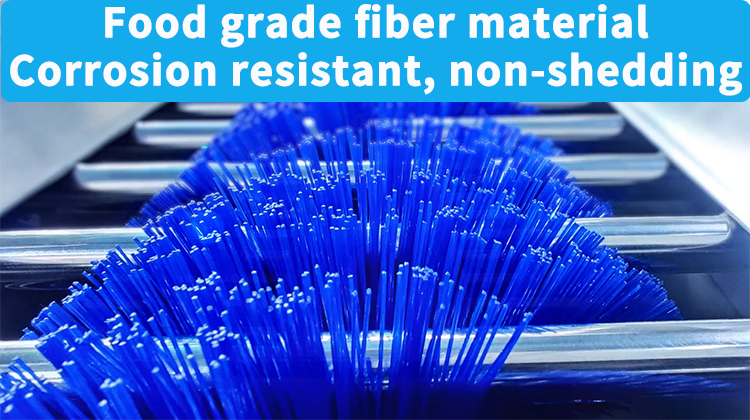

- Boot Cleaning: Sturdy brushes and pressure jets remove debris from footwear.

-

.jpg)

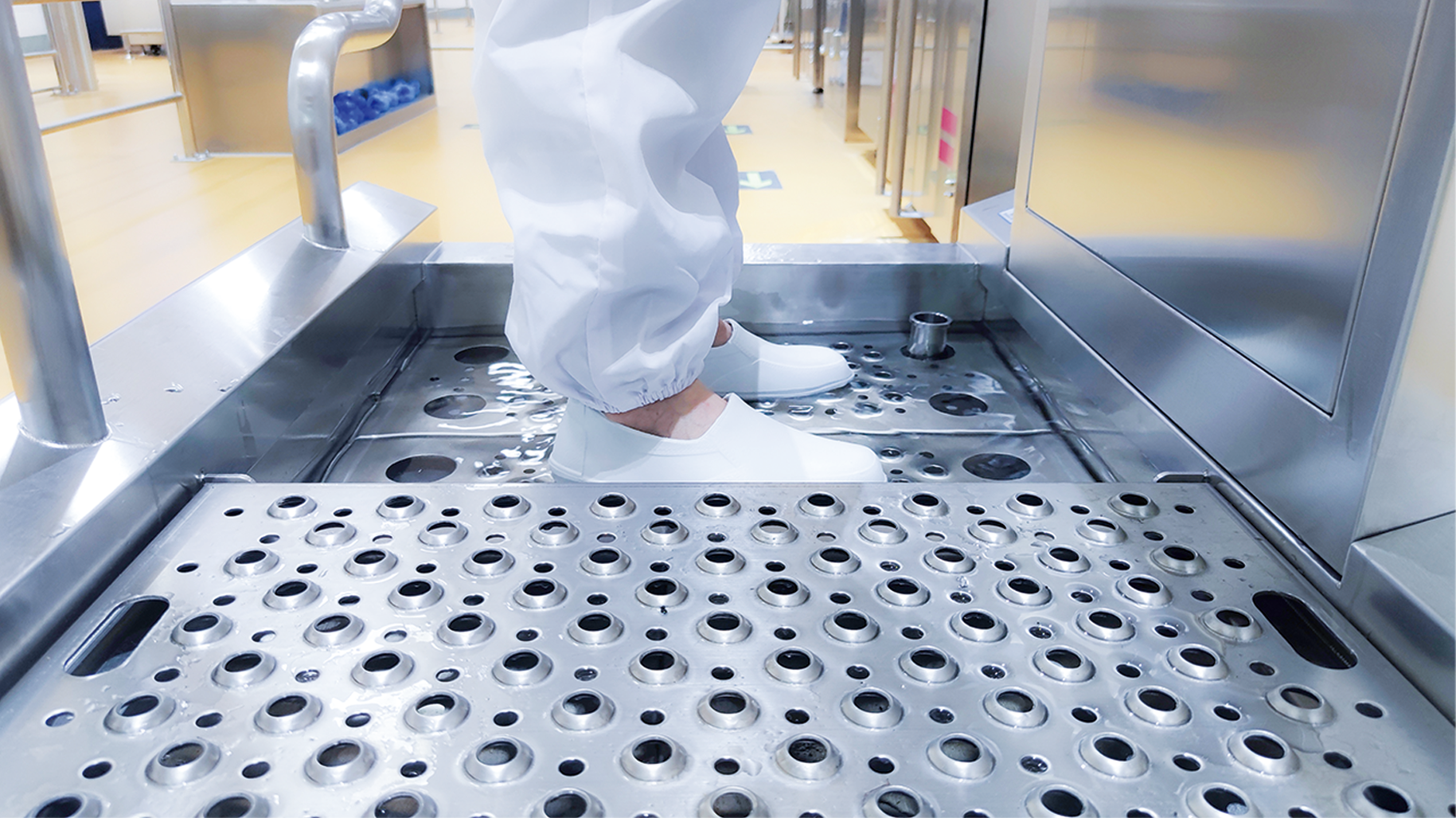

- Boot Disinfection: A built-in disinfection pool filled with sanitizing solution ensures thorough sole decontamination.

-

This integration ensures employees complete a full hygiene cycle in under 60 seconds, minimizing downtime.

- High-Capacity Performance

Despite its compact footprint, the PBW-25 serves 60 employees effortlessly. It can accommodate 3 to 4 employees on the hygiene station at

the same time, with a throughput of up to 3 users per minute without congestion, which improves the cleaning and sanitizing efficiency. That

means 60 employees can finish the cleaning and sanitzing in 20 minutes. Anti-microbial materials and self-cleaning mechanisms ensure

continuous operation, even during shift changes.

- Regulatory Compliance

The PBW-25 adheres to global standards, including HACCP, ISO 22000, and GMP. Automated timers and usage logs provide audit trails,

simplifying compliance reporting for food safety inspectors.

- Sustainability Focus

As a responsible hygiene equipment manufacturer, WONE prioritizes eco-efficiency. The PBW-25 uses 40% less water than traditional sinks

and energy-efficient dryers, aligning with green initiatives.

Why Choose WONE as Your Hygiene Station Manufacturer?

Selecting the right hygiene station manufacturer is critical for long-term success. WONE stands out through:

- Industry-Specific Expertise: Over 15 years of specialization in food plant hygiene solutions.

- Hygiene Solution Plant Capacity: We can do the hygiene solution plant according to the facility layout.

- Durability: Stainless steel construction is resistant to corrosion, chemicals, and heavy-duty use.

- Support Services: Installation, training, and maintenance packages to ensure seamless adoption.

The Role of Hygiene Equipment Manufacturers in Food Safety

Hygiene equipment manufacturers like WONE play a pivotal role in safeguarding food supply chains. By developing innovative solutions

such as the PBW-25, they empower facilities to:

Reduce contamination incidents by 70% (based on internal studies).

Streamline workflows, boosting productivity.

Demonstrate commitment to consumer safety during audits.

Implementing a Food Plant Hygiene Solution: A Step-by-Step Guide

Assessment: Evaluate current hygiene gaps and employee traffic patterns.

Installation: Position the PBW-25 at key entry/exit points (e.g., processing area entrances).

Training: Conduct workshops on proper hand and boot hygiene cycles.

Monitoring: Use built-in IoT sensors to track usage and disinfectant levels remotely.

Case Study: Enhancing Hygiene in a Dairy Processing Plant

A mid-sized dairy plant struggling with frequent audit failures installed two PBW-25 units. Results within three months:

- 90% improvement in hand hygiene compliance.

- 50% reduction in water consumption.

- Zero contamination-related downtime.

Conclusion: Elevate Your Hygiene Standards with WONE

For food workshops with 60 employees, the PBW-25 Hygiene Station is more than a product—it’s a food plant hygiene solution that transfo-

rms safety, efficiency, and compliance. As a trusted hygiene equipment manufacturer, WONE invites you to explore how our technology can

protect your workforce, products, and reputation.

Contact WONE today to schedule a consultation and revolutionize your facility’s hygiene protocols.