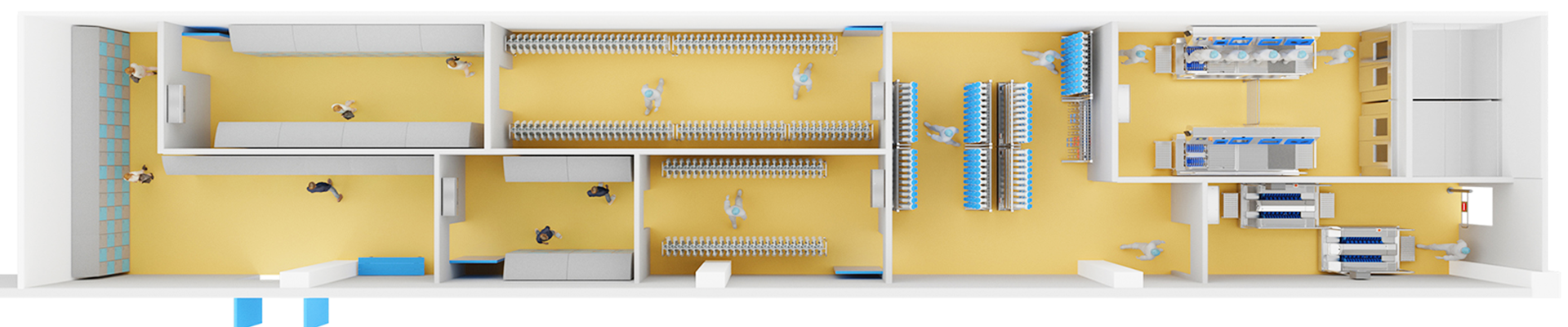

Changing Room

Hygiene Planning and Design Solution for Changing Room

Let's talk about something that might not seem glamorous but is absolutely vital in food factories: the employee changing room. Getting its design right isn't just about convenience

—it's a major shield for food safety. Here's why planning these spaces carefully is so important:

1. To Keep Contamination Out (The priority Job):

Think of the changing room as a hygiene checkpoint. It's the crucial barrier between the outside world—where we pick up dirt, dust, and germs—and the spotless areas where food is

handled. A well-thought-out layout and traffic flow make sure workers don't accidentally bring those outside contaminants in with them.

2. To Keep “Dirty” and “Clean” Completely Separate:

A good changing room has a clear split. One side is for your daily clothes and personal items (the “dirty side”). The other side is where spotless work uniforms and gear are stored

and put on (the “clean side”). This physical separation stops cross-contamination in its tracks.

3. To Meet the Rules & Pass Audits:

Major food safety standards like BRCGS, SQF, and local health codes don't just suggest having changing rooms—they require them. Proper planning from the start ensures your

facility checks all the boxes for a hygienic design, helping you stay compliant and audit-ready.

So, How To Plan A Good Changing Room?

It's not one-size-fits-all. The design usually comes down to a few key things:

- how clean the production area needs to be (think ready-to-eat foods vs. raw ingredients),

- number of employees in the workshop

- whether the factory area is dry or wet,

- and of course, the project budget.

If you have a new food factory and need a hygienic plant and design of a changing room, or purchase hygiene equipment for new changing rooms,

please feel free to contact us.

.png)