How to choose a suitable hygiene station for your food factory?

Hygiene cleaning stations, as a personnel hygiene barrier solution, are being chosen by more and more food companies. So, how do food

companies choose suitable hygiene sanitation stations for their own factories?

Selecting the right personnel hygiene cleaning and sanitation station for a food factory requires considering several key factors to ensure

effectiveness, compliance, and convenience. Here is a guide on how to make the right choice:

1. Evaluate regulatory requirements

1.1- Compliance standards:

- Be familiar with local and international food safety regulations that dictate personnel hygiene practices. Make sure the selected station meets these standards.

2. Location and accessibility

2.1- Strategic layout:

- Place sanitation stations at key entrances to food processing areas to ensure easy access for all employees.

-

.jpg)

.jpg)

.jpg)

2.2- Traffic flow:

- Consider employee flow, prevent congestion, and ensure a smooth transition to production areas.

3. Station design and functionality

3.1- Handwashing facilities:

- Make sure the station includes a hands-free faucet, soap dispenser, and paper towel dispenser or air dryer to minimize contamination.

-

.png)

.png)

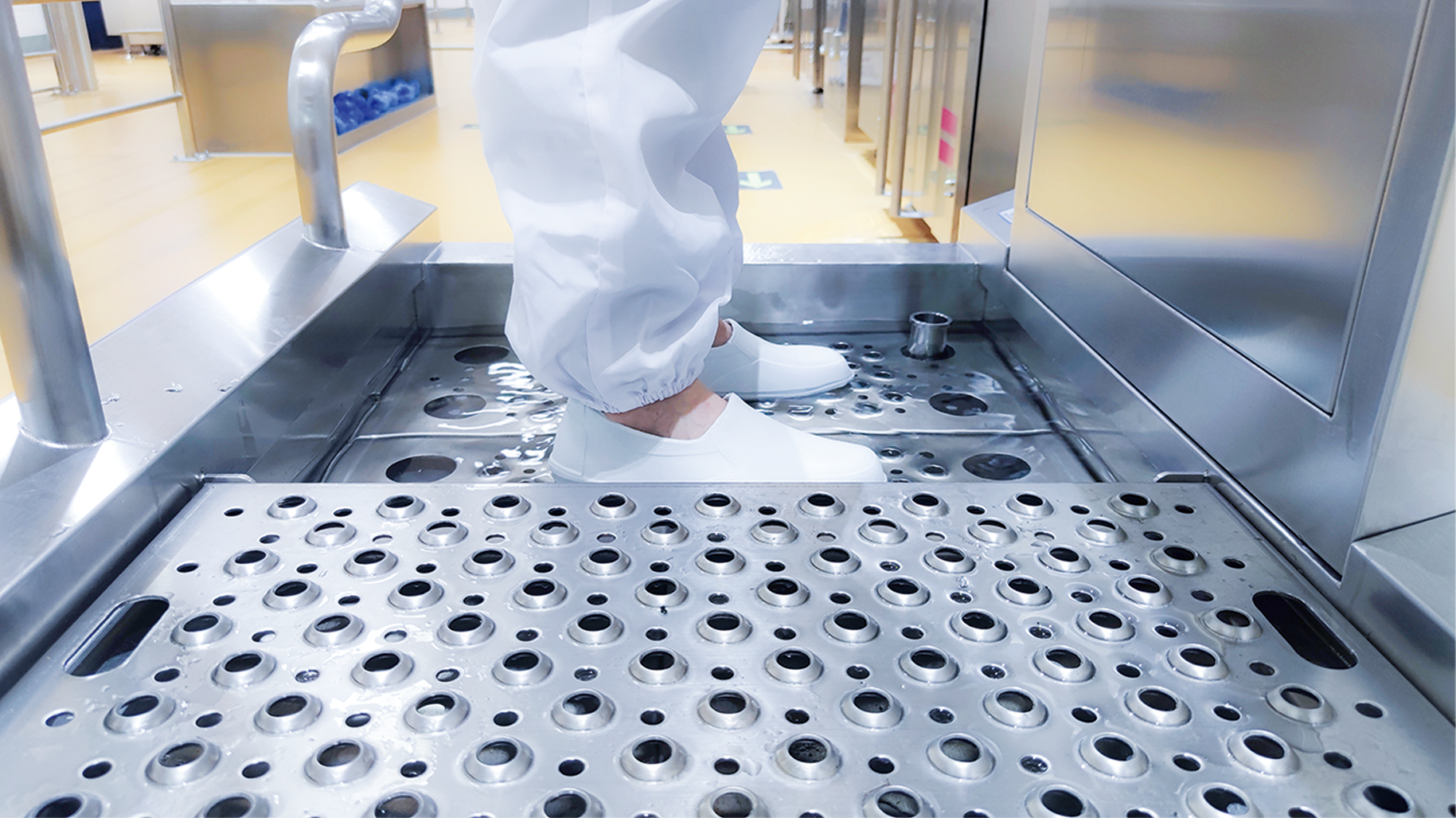

3.2- Disinfection options:

- Choose a spray-type disinfectant to disinfect your hands, and a disinfection pool to disinfect your shoes and boots to enhance hygiene

-

3.3- Space and size:

- Choose a cleaning station design that can accommodate the expected number of users or is efficient without being overcrowded, allowing for efficient handwashing and sanitizing.

4.1- Corrosion-resistant materials:

- Choose materials that are easy to clean and resistant to corrosive cleaning chemicals, such as stainless steel.

4.2- Durability:

- Ensure that the workstation can withstand frequent use without wear and tear and remain functional for a long time.

5.1- Accessible design:

- Choose a design that is easy to clean and maintain, including removable parts or easily wiped surfaces.

-

.png)

.png)

6.1- Training integration:

- Consider how to integrate handwashing stations into employee training programs, emphasizing the importance of hygienic habits.

6.2- Signage:

- Use clear signs to guide employees on proper handwashing techniques and the importance of hygiene.

-

.jpg)

.png)

In addition, you can also match your needs according to the functions and characteristics of each hygiene sanitation and cleaning station, and

choose the cleaning station that suits you.

PBW-25

- Employees can finish washing, drying, and disinfecting their hands, as well as cleaning and sanitation of footwear.

- One machine is suitable for 60 staff workshops.

- Size of L2990*W1045*H1640mm

-

.jpg)

PBW-24

- Employees can finish washing, drying, and disinfecting hands as well as boot disinfection.

- One machine is suitable for 60 staff workshops.

- Size of L1610*W995*H1555mm

-

PBW-23

- Employees can finish hand disinfection as well as boot cleaning and sanitation.

- One machine is suitable for 60 staff workshops.

- Size of L2470*W1045*H1510mm

-

PBW-21T

- Employees can finish disinfecting their hands and boots.

- One machine is suitable for 60 staff workshops.

- Size of L1500*W1020*H1390mm

-

PBW-41E

- Employees can finish washing, drying, and disinfecting hands as well as boot disinfection.

- One machine is suitable for 30 staff workshops.

- Size of L640*W940*H1715mm

-

By considering these factors, food factories can choose a personnel sanitation station that can strengthen sanitation habits, meet safety

standards, and support employee food safety culture.