Changing Room Design for Food Processing Industry

The changing room design for food processing industry is a critical component of modern food safety protocols, particularly in facilities like

100,000-level cleanrooms and wet process production workshops. With a workforce of 20 employees (8 men and 12 women), this article

delves into a tailored changing room design for food processing workshop industry that integrates advanced sanitation technologies, gend-

er-specific layouts, and unidirectional workflows. By prioritizing contamination control, ergonomic efficiency, and compliance with global sta-

ndards, this solution exemplifies how strategic design can safeguard both product integrity and worker safety.

Applicable Scenarios: Addressing Unique Challenges

The changing room design for food processing industry outlined here is engineered for:

- 100,000-level cleanrooms: Controlled airflow, HEPA filtration, and particulate monitoring to meet ISO Class 8 standards.

- Wet process environments: Slip-resistant flooring, moisture-resistant materials, and high-top rain boots to mitigate hazards.

- Gender-balanced workforce: Separate but equitable men’s and women’s changing areas to accommodate privacy and workflow needs.

This changing room design for food processing industry is not merely a regulatory requirement—it is a proactive measure to prevent cross-

contamination in high-risk settings.

Entering Route: A Four-Step Hygiene Protocol

1. External Shoe Change Zone

The changing room design for food processing industry begins with a double-sided low shoe cabinet. Employees replace their outdoor footw-

ear with turnover slippers, ensuring personal shoes never enter the clean zone. This step is foundational to the changing room design for foo-

d processing industry, as it physically isolates external contaminants. The cabinet's spacious layout allows simultaneous use by multiple emp-

loyees, reducing bottlenecks during shift changes.

.png)

.png)

2. Work Boot Room

Next, workers proceed to the boot room, a hallmark of the changing room design for food processing industry. Here, they exchange slippers

for high-top rain work boots which are placed on the shoe and boot drying/disinfection machines. These units employ UV-C light and heated

airflow to eliminate moisture, odors, and pathogens—critical in wet environments where damp footwear can harbor bacteria.

.png)

.png)

The changing room design for food processing industry divides clothing changes into two phases:

- Outer changing area: Personal attire is stored in numbered ABS cabinets, which resist corrosion and microbial growth.

- Inner changing area: Sterilized work uniforms are retrieved from disinfection cabinets.

.png)

.png)

.png)

A handwashing station (PHW-F3E) bridges the two zones, mandating hand hygiene before handling clean garments. This step in the changing

room design for food processing industry minimizes pathogen transfer during clothing transitions.

4. Personal Washing and Disinfection Before Entering the Workshop

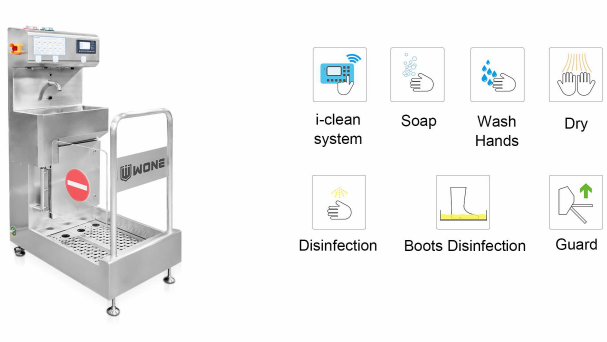

Employees then enter a washing/disinfection room equipped with the PBW-41E personnel hygiene station. This phase of the changing room

design for food processing industry enforces a one-way flow through automated handwashing, and air showers. The air shower's HEPA-filter-

ed jets remove particulates from clothing, a non-negotiable step for maintaining 100,000-level cleanroom integrity.

Leaving Route: Containing Contamination During Exit

When exiting, personnel clean their rain boots using the PBW-31W small boot washer. This machine, a flexible feature of the changing room

design for food processing industry, scrubs and disinfects footwear in a compact, wall-mounted unit. By segregating exit routes from entry pa-

ths, the design ensures a strict one-way workflow, preventing cross-contamination.

.png)

Key Features of the Changing Room Design for Food Processing Industry

1. Double-Sided Shoe Cabinets

Purpose: Separate personal shoes from sanitized slippers.

Advantage: Eliminates cross-contamination while optimizing space.

2. Boot Drying and Disinfection Machines

Purpose: Sanitize and dry high-top rain boots between shifts.

Advantage: Reduces microbial risks in wet environments.

3. ABS Cabinets and UV Disinfection wardrobe

Purpose: Store personal and work clothing securely.

Advantage: Non-porous surfaces and UV cycles inhibit pathogen growth.

4. PHW-F3E Handwashing Stations

Purpose: Enforce hygiene between changing phases.

Advantage: Touchless operation reduces surface contact.

5. One-Way Flow Enforcement

Purpose: Guided by PBW-41E stations and air showers.

Advantage: Prevents backtracking, a major contamination risk.

Conclusion: A Model for Safety and Efficiency

The changing room design for food processing industry detailed here is more than a compliance checklist—it is a blueprint for operational ex-

cellence. By harmonizing gender-specific layouts, automated sanitation, and unidirectional workflows, this design addresses the unique dema-

nds of wet production and high-cleanliness environments. For facilities with 8 men and 12 women, the changing room design for food proces-

sing industry ensures equitable access while maintaining rigorous hygiene standards.

In summary, this changing room design for food processing industry underscores the importance of integrating technology, ergonomics, and

regulatory adherence. From double-sided cabinets to flexible boot washers, every element is purpose-built to protect both workers and consu-

mers, solidifying its role as a cornerstone of food safety.