What to consider when planing a changing room in food factory?

In food factories, the changing room is a key transition area connecting the non-clean area and the clean area. Its planning directly affects

production hygiene and safety, employee efficiency and compliance. The following are the key points that need to be paid attention to during

planning:

I. Core principle: prevent cross contamination

1. Strict zoning management

1.1-Separation of "dirty area" and "clean area":

Clearly divide the shoe changing area (external shoe storage), dressing area (changing work clothes), hand washing and disinfection area

(before entering the clean area) and secondary dressing area (such as high clean area requires protective clothing).

1.2-One-way flow design:

The path of employees from the entrance to the production area is irreversible to avoid the intersection of personnel in the clean area and

non-clean area.

1.3-Physical isolation:

Block the direct connection between the clean area and the outside world through access control, air shower room or buffer room.

2. Separation of human flow and logistics

The employee channel and material channel are completely independent to prevent raw materials, packaging materials, etc. from entering

the production area through the dressing room.

1. Air hygiene air quality management

Negative pressure/positive pressure design: The clean area maintains positive pressure to prevent the inflow of external polluted air; the

shoe-changing area can be set with negative pressure to avoid the spread of odor.

Ventilation system: The number of air changes per hour must meet the standard (such as ≥15 times), equipped with high-efficiency filters

(such as H13-level HEPA) and regularly maintained.

Temperature and humidity control: The temperature is recommended to be 18-25℃, and the humidity is ≤60% to inhibit the reproduction

of microorganisms.

Alternatively, you can consider introducing an air disinfection machine with ultraviolet and ozone functions. Use Ultraviolet disinfection

during work-shift, ozone disinfection and deodorization after work.

_18476.png)

.png)

Easy to clean material: The wall is coated with stainless steel or epoxy resin, the ground is coated with non-slip PVC or self-leveling floor,

and the joints are rounded.

No dead corner design: Avoid dust accumulation areas such as the top of the locker and pipes, and use embedded lighting.

3. Configuration of cleaning and disinfection facilities

3.1-Hand disinfection facilities

- Location: It must be set on the necessary route to enter the clean area after washing hands (such as the workshop entrance) to ensure that employees cannot bypass it.

- Equipment type: Non-contact induction disinfector, to avoid secondary contamination of hands, it is recommended to use an infrared induction spray device.

- Disinfectant selection:Food-grade alcohol (75% ethanol): Suitable for routine disinfection, fast evaporation and no residue.

- Hydrogen peroxide complex (such as 0.5% concentration): For high-risk areas (such as ready-to-eat food workshops), the bacteric-idal spectrum is wider.

- Dosage control: The recommended spray volume is 1.5-2ml each time, which is controlled by nozzle design or sensor to avoid waste.

-

.png)

3.2-Sole disinfection pool or cleaning brush

- Shoe disinfection: The depth of the sole disinfection pool is ≥15cm, and the length covers more than two steps. The disinfectant is replaced regularly (such as sodium hypochlorite solution).

-

- Sole scrubbing: Use a durable, food-grade polyester fiber brush. Combined with a special cleaner for shoes and boots, it can effecti-vely inhibit bacteria. Low-foam concentrate, more thorough cleaning, more economical detergent. Sensors automatically sense cleaning.

-

.png)

3.3-Workwear/tool disinfection facilities

Ultraviolet Ozone disinfection wardrobe:

UV lamps are integrated in the cabinets, and disinfection is scheduled every day (such as 30 minutes during lunch break).

The cabinet body is made of stainless steel, and the inner wall is polished to reduce shadow dead corners.

.png)

.jpg)

III. Key points of functional area planning

1. Shoe changing area

The external shoe cabinet is placed separately from the internal work shoe cabinet, and the bottom of the cabinet is 20cm off the ground for

easy cleaning.

Use height difference design (such as 10cm steps) or color marking to distinguish clean and non-clean areas.

2. Dressing area

- Capacity calculation: Designed according to the maximum number of shifts, the storage space per person is ≥0.2m³, and the work clothes hanging area is completely isolated from the casual clothes storage.

- Intelligent management: Optional electronic locker system, record employee access time, integrated work clothes washing cycle reminder function.

3. Hand washing and disinfection area

Standard non-contact faucet, antibacterial hand sanitizer, 75% alcohol spray and hand dryer.

Install surveillance cameras or electronic clock-in to ensure that employees complete the complete hand washing process (refer to WHO six-

step method).

4. Secondary dressing area (optional)

For high-risk areas (such as ready-to-eat food workshops), add protective clothing wearing areas and air showers (wind speed ≥ 20m/s, time

≥ 15 seconds).

IV. Compliance and scalability

Regulatory compliance

Comply with FDA 21 CFR Part 117, ISO 22000, BRCGS and other standards, and retain verification documents required for third-party audits

(such as airflow visualization reports).

Flexible expansion design

Adopt modular partitions and reserve 20% expansion space to adapt to future production line additions or shift adjustments.

VI. Special scenario considerations

High-risk products (such as infant food): Add a sterile outer packaging removal room, and employees need to remove all personal outer

packaging in the dressing room.

Extreme climate areas: Add a sticky mat + air curtain combination at the entrance of the locker room to block sand, dust or mosquitoes.

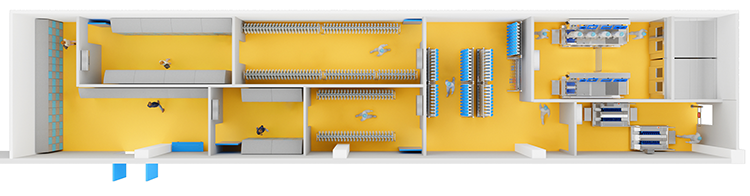

Sample layout (reference)

Through systematic design, the locker room can not only meet compliance requirements, but also become the first line of defense to improve

employee hygiene awareness and reduce the risk of microbial contamination. It is recommended to introduce a HACCP team to conduct risk

assessment during the planning stage to ensure effective monitoring of critical control points (such as hand disinfection).