The Boot Washer Dilemma: Entrance, Exit, or Both? Optimizing Food Workshop Hygiene

In food manufacturing, controlling contamination is a relentless challenge. Among the critical control points, **footwear hygiene** plays a

surprisingly pivotal role. The question of whether boot washers belong at the **entrance, exit, or both** of a food workshop isn't trivial—it

directly impacts product safety, regulatory compliance, and operational efficiency. Let's dissect the factors driving this crucial decision.

Why Placement Matters: The Contamination Control Imperative

Personnel and their footwear are significant vectors for introducing pathogens (like Salmonella, Listeria), soil, allergens, and physical

debris into sensitive production zones. Conversely, boots worn inside high-risk areas (e.g., ready-to-eat processing) can pick up contamina-

nts and spread them to lower-risk areas or other facilities if not properly managed at exits. A strategic boot washer placement strategy mitig-

ates:

1. External Pathogen Intrusion: Preventing contaminants from entering via soles and boot sides.2. Cross-Contamination Between Zones: Halting internal pathogen transfer between departments.

3. Allergen Spread: Containing allergens within designated areas.

The Case for Entrance Placement: The First Line of Defense

For most food workshops, the entrance is the non-negotiable standard location for boot washers.

Primary Barrier Function: Boot washers at entrances act as a critical checkpoint, ensuring all personnel decontaminate footwear before

stepping onto production floors. Integrated systems like the **PBW-24BR** or **PBW-25** combine boot washing, disinfection, and hand

hygiene into a single entry control point, maximizing efficiency and compliance .

Space & Workflow Optimization: Compact, integrated stations are designed for tight entryways, featuring automatic turnstiles that only

grant access *after* the cleaning cycle completes, enforcing protocol adherence .

Regulatory Focus: Audits (FDA, BRC, SQF) prioritize preventing incoming contamination. Entrance boot washers provide documented

evidence of proactive controls .

When Exit Placement Becomes Essential: Containing the Internal Threat

While entrances are standard, high-hygiene and high-risk food facilities increasingly mandate exit boot washers:

High-Risk Zone Containment: In facilities processing ready-to-eat foods, raw meats, or handling potent allergens, exit boot washers prevent

pathogens/allergens *harbored inside the zone* from being tracked out to common areas, locker rooms, or lower-risk zones. This is crucial for

biocontainment.

Protecting Sensitive Equipment: Facilities using sensitive vacuum pumps or packaging lines near processing areas (vulnerable to corrosion

from cleaning chemicals tracked out on wet boots) benefit from exit cleaning to protect capital investment .

Multi-Zone Facilities: Large plants with segregated areas (e.g., raw vs. cooked) often use boot washers at exits *of higher-risk zones before

personnel enter lower-risk zones.

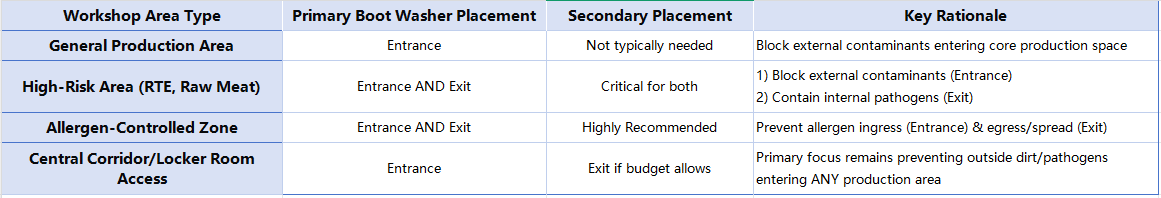

Boot Washer Placement Scenarios & Priorities

Beyond Location: Key Technical & Operational Considerations

Placement is just the start. Effectiveness hinges on design, integration, and maintenance:

1. Integrated Hygiene Stations: Modern solutions like the boot washer combine boot washing (bottom and sides), disinfection (automatic

concentration control), hand hygiene, and access control into a single, auditable unit. This is ideal for entrances, ensuring a complete hygie-

ne sequence .

2. "Smart" Features for Compliance & Data: Systems offering remote monitoring (e.g., i-clean), usage statistics, disinfectant concentration

tracking, and access logs (via facial recognition or cards) provide invaluable data for audits and continuous improvement .

3. Material & Design: 304 Stainless Steel construction, automatic brush systems, and chemical-resistant components are non-negotiable

for durability and cleanability .

4. Complementary Exit Strategies: For exits, simpler systems antimicrobial mats can effectively dry and provide a final disinfection step as

personnel leave, preventing wet floors in common areas .

5. Water & Chemical Efficiency: Automated controllers optimize usage, reducing operational costs and environmental impact – a factor for

frequently used entrance units .

6. Validation & Maintenance: Regular verification of spray patterns, disinfectant concentration, brush wear, and drain function is essential.

CIP (Clean-in-Place) principles can sometimes be adapted for complex boot washer plumbing .

The Verdict: A Risk-Based Approach

There is no universal "entrance vs exit" answer. The optimal strategy requires a risk assessment:

1. Standard Practice: Place robust, integrated boot washer hygiene stations at all personnel entrances to food production workshops. This

is the absolute minimum.

2. Essential for High-Risk/Containment: Add boot washers or dedicated boot sanitation mats at the exits of high-risk zones (RTE, raw

meat, allergen-specific areas) to prevent internal cross-contamination.

3. Dual Stations for Maximum Security: Facilities with the highest hygiene standards often implement **full boot wash stations at both

entrance AND exit of critical zones.

Implementing Your Strategy

Map Your Flows: Diagram personnel movement between zones (raw material intake, processing, packaging, warehousing, rest areas).

Identify contamination ingress and egress points.

Classify Zone Risks: Clearly define low-risk, high-risk, and allergen-controlled zones.Select Appropriate Technology: Choose entrance units with comprehensive cleaning/disinfection/access control. Exit solutions can be

simpler but must effectively remove zone-specific contaminants.

Integrate with SOPs & Training: Placement is useless without enforced procedures and staff training. Use automated turnstiles and monitori-

ng to ensure compliance .

Monitor, Validate, Improve**: Regularly audit boot washer effectiveness (swab tests post-cleaning?), usage data, chemical levels, and main-

tenance records.

Conclusion

The boot washer’s primary home is unequivocally the **entrance** – it is the vital gatekeeper against external contamination. However, sop-

histicated food safety programs recognize that contamination control isn't just about keeping threats *out*; it's also about preventing them

from moving *around* or *escapating*. For high-risk processing environments, **adding boot sanitation at the exit** is a critical step towards

truly comprehensive hazard control. By adopting a risk-based approach that considers product vulnerability, process flow, and regulatory

expectations, food manufacturers can deploy boot washers not just as compliance tools, but as powerful assets in building an unassailable

food safety culture. Investing in modern, integrated systems with smart capabilities further future-proofs this essential defense.