SOP of Open Plant Cleaning in Food Facility

Standardized Operating Procedures (SOPs) exist for open plant cleaning in food processing plants. These SOPs are typically in written form and follow a set of general and logically rigorous

steps. Their core objectives are to effectively remove contaminants, prevent cross-contamination, and ultimately ensure hygiene and safety through disinfection (if necessary).

I. Core Elements of an SOP

Multiple standards and management regulations emphasize the necessity of written cleaning procedures and specify the content that an SOP should include. In summary, a complete

cleaning and disinfection SOP should at least clearly define the following elements:

1. Cleaning Area and Objects:

Clearly define the areas to be cleaned (e.g., general workshop, semi-clean workshop, clean workshop) and specific equipment, facilities, and tools (e.g., floors, walls, workbenches, processing equipment exteriors, drains, utensils,Conveyorsetc.).

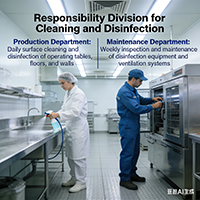

2. Division of Responsibilities:

Assign the responsible department or personnel to perform the cleaning and disinfection tasks.

- Methods: Clearly define whether dry or wet cleaning is used, and the specific operating steps.

- Frequency: Determined based on regional risk and production status, such as "after-shift every day or as needed," "once a week," etc.

- Chemicals: Specifies the types, concentrations, and preparation methods of cleaning and disinfecting agents to be used.

-

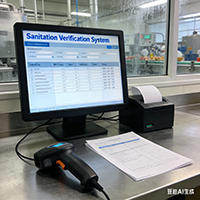

4. Monitoring and Validation Measures:

- Inspection: Inspections must be conducted after cleaning/before production.

- Validation Methods: Includes sensory inspection (visual inspection), ATP bioluminescence testing, microbial smear testing, etc., to confirm the effectiveness of cleaning and disinfection.

- Records: Maintain cleaning, disinfection, and validation records.

-

II. Standardized Cleaning and Disinfection General Process (Seven-Step Method)

1. Preparation and Dismantling:

- Preparation: Gather the necessary personal protective equipment (PPE), tools, equipment, and chemicals.

- Dismantling: According to SSOP requirements, provide accessibility for thorough cleaning by removing removable parts such as equipment covers, conveyor belts, and trays. Never p-lace food contact equipment on the ground.

- Lock-in Tag (LOTO): Implement energy isolation for equipment according to safety regulations to ensure the safety of cleaning personnel.

2. Dry Cleaning (Pre-cleaning):

Use tools such as scrapers, brushes, and brooms to remove all large, dry dirt and food scraps from equipment and floors. This step significantly improves the efficiency of subsequent wet

cleaning.

3. Pre-rinse:

Use hot water (approximately 54°C) and low pressure to rinse from top to bottom and from side to side, removing all visible dirt. The purpose is to melt grease and wash away loose dirt,

preparing the surface for the cleaning agent to work. Control water pressure to prevent splashing and cross-contamination.

4. Cleaning Agent Application and Scrubbing:

Spray or apply a suitable cleaning agent (such as an alkaline foam cleaner) to cover all surfaces to be cleaned and maintain contact time (e.g., 15-20 minutes) to break down grease and

biofilm. Manually scrub using designated brushes, scouring pads, etc.

.png)

5. Intermediate Rinse:

Rinse thoroughly with water (hot water if necessary) to remove all loosened dirt and cleaning agent residue. This is a crucial step to ensure effective contact of the disinfectant with the surface.

6. Disinfection:

When necessary (especially for food contact surfaces), disinfect surfaces using approved disinfectants (such as chlorine-based disinfectants, quaternary ammonium salts, alcohol, etc.).

Ensure that the disinfectant concentration and contact time comply with the manufacturer's instructions.

After disinfection, rinsing with clean water is usually required unless the disinfectant instructions specify that rinsing is unnecessary.

7. Inspection and Assembly:

- Inspection: All personnel performing inspections must be trained. Use flashlights, inspection mirrors, and other tools to inspect all equipment and environmental surfaces to ensure they are free of contaminants and chemical residues. Perform ATP or microbiological validation if necessary. Areas found to be uncleaned must be re-cleaned and recorded.

- Assembly: Reassemble the equipment according to the SSOP guidelines and ensure that all components are correctly installed before production.

III. Specific Requirements for Open Plant

This standard provides clear SOP examples for different areas of supermarket food processing and sales premises. The principles also apply to similarareasin food factories:

1. Clean Operating Areas (Dedicated Rooms, Dedicated Zones):

- Equipment, facilities, and tools should be cleaned and disinfected daily.

2. Semi-Clean Operating Areas (Cooking and Processing Areas) and General Operating Areas (Preliminary Processing, Cutting, Warehouse):

- Equipment, facilities, and tools should be cleaned and disinfected periodically.

IV. Direct Evidence Supporting the Existence of SOPs

1. Article 5.11.1 of the AIB, "Key Requirements," clearly states: "Businesses should have written cleaning procedures."

2. EU EC 852/2004, Annex II – Chapter I & V, Food Hygiene Regulation, requires that food premises must be kept clean and that cleaning and disinfection procedures must be established and

implemented.

3. CAC/RCP 1-1969 General Standard for Food Hygiene: Key requirement: A cleaning and disinfection plan must be established. Specific requirements: Cleaning objects, methods, frequency,

responsible persons.

4. FSSC 22000 (ISO 22000 + industry PRP) industry technical specifications (such as ISO/TS 22002-1) clearly state: Cleaning and disinfection procedures must be documented.

Including: Floors, walls, drains, equipment exterior surfaces.

5. BRCGS Food Safety, Clause 4.11 – Housekeeping and Hygiene clearly requires: Written cleaning and disinfection procedures. Clearly defined: Areas, methods, chemicals, frequency,

validation methods.

6. IFS Food requirements: Cleaning and disinfection must be documented. Must cover the entire processing environment. Audits will verify consistency between the site and the documentation.

Cleaning of open plant in food processing factories has highly standardized SOPs. This Standard Operating Procedure (SOP) is a written procedure based on risk analysis (differentiating by

area and frequency), with a seven-step cleaning and disinfection method as its core operating process. It also emphasizes effectiveness verification and recording, forming a complete hygiene

management system. Enterprises must develop and implement specific written cleaning and disinfection procedures based on their own products, processes, and factory layout, referring to

the above general framework and standard requirements.