Don't overlook the harm that hygiene issues with work boots can cause to food safety

In the daily operation of food factories, we often focus on key aspects such as raw material acceptance, production equipment, and personnel hand hygiene, but easily

overlook a seemingly insignificant yet highly risky source of contamination—the work boots worn by employees. Like a "walking source of contamination," they silently

bring external pollutants into clean areas, becoming a key medium for cross-contamination and the spread of microorganisms. Here will, in conjunction with authoritative

standards and regulations, deeply analyze the specific hazards caused by poor hygiene management of work boots and explain why it is an indispensable part of the

food safety system.

.png)

I. Work Boots: An Underestimated "Bridge" for Cross-Contamination

Work boots are in direct contact with the ground, serving as the most direct carrier connecting the external environment, general work areas, and clean/quasi-clean work

areas. If shoes are not cleaned promptly after leaving the workshop, it can be disastrous for the hygiene of the changing room or the shoe disinfection pool when

re-entering the workshop. Two main pathways for work boot contamination:

1. Bringing external contaminants into the workshop:

Soil, dust, organic matter (such as food scraps and wastewater), and a large number of microorganisms (such as Salmonella and Listeria) attached to these materials,

picked up from factory roads, warehouses, restrooms, etc., can be carried into the production workshop through the soles of shoes.

2. Causing cross-contamination between different clean areas:

When employees wear the same pair of shoes to walk between different areas (such as raw material handling areas, processing areas, and packaging areas), contamin-

ants from low-cleanliness areas can be carried to high-cleanliness areas. In severe cases, this can lead to the contamination of ready-to-eat food with pathogens.

The national mandatory standard GB 14881-2013, *National Food Safety Standard - General Hygiene Specifications for Food Production*, and its 2025 draft for public

comment, both clearly stipulate that: "Shoe-changing (wearing shoe covers) facilities or work shoe disinfection facilities should be provided as needed at the entrance of

the production workshop and in necessary areas within the workshop**." This establishes a mandatory requirement for the hygiene management of work boots at the

regulatory level, and it is by no means an optional choice.

.png)

.png)

.png)

II. Specific Hazard Analysis: From Microbial to Physical Contamination

Ignoring work boot hygiene will directly lead to the following types of food safety hazards:

1. The risk of microbial contamination is surging.

The damp interiors and crevices of shoes and boots, often containing nutrient residue, become breeding grounds for microorganisms. The AIB standard "Prerequisite"

points out that improperly managed shoe disinfection pools can themselves become sources of contamination and points of diffusion for microbial aerosols. When

employees move within the workshop, microorganisms from their shoes and boots can detach and contaminate the floor, low-lying surfaces of equipment, and

subsequently, through personnel movement, equipment vibration, or airflow, contaminate food contact surfaces and even the products themselves. This risk is

particularly critical in clean work areas (such as cold processing rooms and inner packaging rooms).

2. Risks of Foreign Object Contamination and Chemical Contamination.

Foreign objects that shoes and boots may carry and detach include small stones, metal shavings, plastic pieces, and loose threads. Furthermore, if employees have

walked through areas where chemicals are stored or used, the soles of their shoes may be contaminated with disinfectants, lubricants, and other chemicals, which can

be carried into food production areas, causing chemical contamination.

3. Disruption of the Overall Hygiene and Control System:

Dirty work boots continuously contaminate the floors of changing rooms, air showers, and workshop passageways, significantly increasing the difficulty and cost of

environmental cleaning. This also renders facilities such as disinfection pools and air showers, intended for microbial control, largely ineffective, or even useless. The

document repeatedly lists the absence or ineffectiveness of "work shoe disinfection facilities" in the "changing and disinfection" process as a key risk point, precisely

because of this.

III. Establishing an Effective Hygiene Management Barrier for Work Boots

Recognizing the hazards is the first step; establishing and implementing effective control measures is crucial. The document provides a systematic solution:

1. Zoning Management and Dedicated Shoe System:

In accordance with international standards such as the BRC Global Food Safety Standard and FSSC 22000, physical isolation and personnel flow control should be

implemented for areas with different cleanliness levels (e.g., low-risk areas, high-risk areas, high-concern areas). One of the most effective methods is to implement a

"zone-specific work boot" system, where employees change into shoes of specific colors or markings when entering different zones, fundamentally cutting off the path

of cross-contamination through footwear. This is a more thorough control measure than simple disinfection.

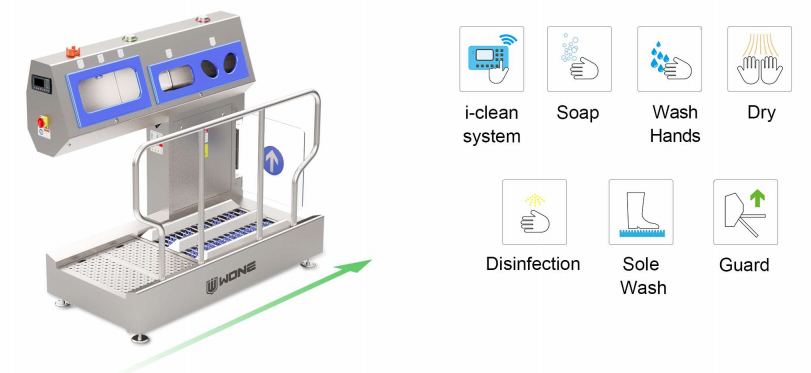

2. Establish Effective Cleaning and Disinfection Facilities

When the same pair of shoes must be worn in different areas, or as a supplementary measure, effective shoe cleaning and disinfection facilities must be set up at key

entrances:

2.1-Effective disinfection before entering the workshop:

At the entrance to the clean work area, a shoe disinfection pool or automatic disinfection equipment that meets specifications should be set up. The size of the

disinfection pool must ensure that the soles of employees' shoes are completely submerged, and the concentration of the disinfectant (such as the effective chlorine

concentration) needs to be monitored and changed regularly to ensure its continued effectiveness.

_72110.png)

___________________________________________________________________________________________________________________________

2.2-Mandatory cleaning upon leaving the workshop:

Install walk-through boot washing machines or manual boot washing facilities at the workshop exit to ensure that visible dirt on the soles and uppers of employees' shoes is thoroughly

removed before leaving, preventing contamination of the changing room. Immediate washing upon leaving the workshop is the optimal time for cleaning work shoes.

.png)

.png)

_______________________________________________________________________________________

________________________________________________________________________________________

_________________________________________________________________________________________

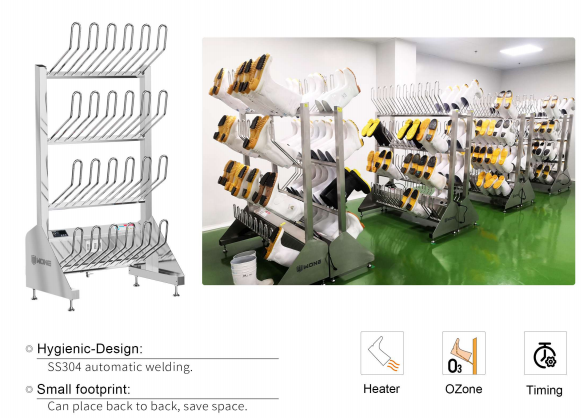

2.3-Post-shift drying and disinfection:

Install shoe dryers (which can be combined with ozone disinfection) in the changing room to dry and internally disinfect cleaned work boots, preventing microbial growth

and providing dry and comfortable footwear for the next day.

.png)

.png)

.png)

Clear systems:

The company should clearly stipulate the frequency and standard operating procedures (SOPs) for cleaning, disinfecting, replacing, and storing work boots in its hygiene management

system.

Adequate training:

Provide training to all employees, including new hires, contractors, and visitors, ensuring they fully understand the importance of work boot hygiene and are proficient in the correct use

of related facilities.

Inspection and monitoring:

Management should include the cleanliness of work boots in daily inspections and regularly monitor the environment (especially changing rooms and entrances) for microbial

contamination to verify the effectiveness of footwear control measures.

The hygiene management of work boots is a crucial yet easily overlooked "last mile" in the food factory's cross-contamination prevention system. It not only meets the compliance

requirements of domestic and international standards and regulations such as GB 14881, but also directly reflects the company's food safety culture and management sophistication.

Behind a pair of clean work boots lies a complete system encompassing design, facilities, execution, and supervision.

Remember: Food safety is paramount; risks often lurk in the details. Starting today, re-examine and strengthen the "foot defenses" of your factory. Don't let seemingly insignificant work

boots become the weakest link in your food safety edifice.