The Double Duty Boot Washer for Food Safety

Views: 440 Update date: Aug 05,2025

The Double Duty Boot Washer for Food Safety

Why Traditional Methods Fail

- Manual scrubbing leaves 35% of boot surfaces untouched

- Shared brush stations become pathogen reservoirs (Listeria survives 12+ days on bristles )

- Exit contaminants hitchhike via boots to break rooms, offices, and external environments

Technical Edge: Engineering for Food Safety

Modern two-way systems like the PBW-61 model feature:

- 304 stainless steel bodies with sloped drainage to prevent water pooling

- two-way boot washer, one machine solve the boot hygiene at entrance and exit

- locked cleaning chemical to ensure the safety

- Self-cleaning brushes that purge debris after each cycle

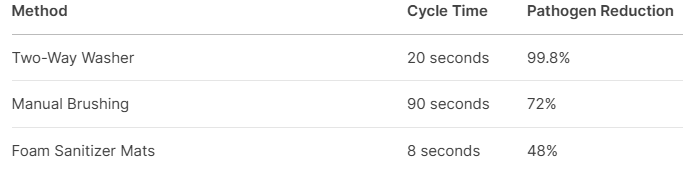

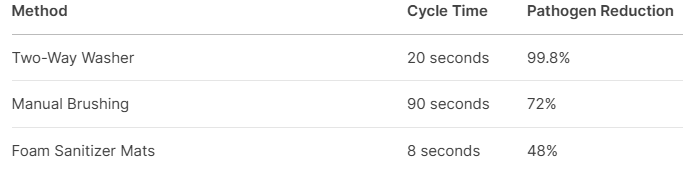

Table: Performance Comparison of Boot Sanitation Methods

Prev: Hygiene Hygiene Station:Smart Personal Hygiene Manager for Your Food Factory

Next: Clean & Sanitize Boots Footwear: A Non-Negotiable Protocol for Food Factory Safety

In the high-stakes world of food manufacturing, where a single pathogen can trigger catastrophic recalls, food factory managers are deploy-

ing an ingenious defensive weapon: the two-way boot washer. This sensor-activated system doesn't just clean work boots—it transforms

them into controlled vectors of sanitation at both entry and exit points, creating a dynamic barrier against cross-contamination.

How Dual-Path Protection Works

1. Entry-Side Boot Cleaning and Sanitization:

- Before workers step into production zones, step into the boot washer, sensors activate rotating food-grade polypropylene brushes that scrub soles and uppers with cleaning solution. This eliminates external contaminants like soil, manure, or parking lot residues .

2. Exit-Side Decontamination:

- When leaving processing areas, the same system triggers a more intensive cycle. Brush soles and uppers with cleaning chemical remove organic matter (blood, grease, produce debris), while disinfectants neutralize pathogens specific to internal processes .

3. Automated Precision:

- The system logs each cleaning event, enabling traceability for audits .

Why Traditional Methods Fail

- Manual scrubbing leaves 35% of boot surfaces untouched

- Shared brush stations become pathogen reservoirs (Listeria survives 12+ days on bristles )

- Exit contaminants hitchhike via boots to break rooms, offices, and external environments

Technical Edge: Engineering for Food Safety

Modern two-way systems like the PBW-61 model feature:

- 304 stainless steel bodies with sloped drainage to prevent water pooling

- two-way boot washer, one machine solve the boot hygiene at entrance and exit

- locked cleaning chemical to ensure the safety

- Self-cleaning brushes that purge debris after each cycle

Table: Performance Comparison of Boot Sanitation Methods