Brush Your Shoes First, Then Wash Your Hands: The Non-Negotiable Sequence for Meat & Seafood Plant Safety

In the high-stakes environment of meat and seafood processing, where product safety is paramount and contamination risks are ever-pres-

ent, employee hygiene isn't just a good practice – it's the critical first line of defense. One specific protocol stands out for its simple logic and

profound impact: brushing boots BEFORE washing hands upon entering the workshop. Understanding and strictly adhering to this sequen-

ce is fundamental to protecting product integrity and consumer health.

Why the Sequence Matters: Breaking the Chain of Contamination

Imagine walking across the plant grounds. Your boots inevitably pick up dirt, dust, organic matter, and potentially harmful microorganisms

from the external environment, or non-processing areas. If you were to wash your hands first:

Contaminated Boots to Hands: While washing, you might adjust your stance, touch your boots, or simply have water splash up from the sink

onto your boots and then back onto your hands or arms. This transfers the external contaminants from your boots to your newly cleaned

hands.

Hands to Product/Surfaces: You then enter the processing area and touch equipment, surfaces, or the product itself with hands that have

just been re-contaminated by your boots.

Boots to Floor: Your still-dirty boots then track those external contaminants directly onto the critical hygiene zone floor of the processing area.

The Correct Protocol: A Two-Step Barrier

1. Brush Boots FIRST (Using the Boot Cleaning Machine):

Purpose: To physically remove the bulk of visible dirt, debris, and microorganisms picked up before entering the high-hygiene area.

Action: Step firmly onto the boot cleaning machine. Ensure all sides of the boots (soles, sides, heels, toes) make contact with the rotating

brushes or scrapers. Use the full duration the machine is designed for (usually 5-10 seconds per foot). The agitation and scraping action

dislodge and trap contaminants.

Result: The primary source of external contamination (your boots) is significantly reduced before you approach the handwash station.

Purpose: To eliminate microorganisms from your hands, which are the primary tools handling product and equipment.

Action: Use the designated handwash station. Wet hands thoroughly, apply ample soap, and scrub vigorously for at least 20 seconds, cove-

ring all surfaces (palms, backs, between fingers, under nails, wrists). Rinse completely under clean, running water. Dry using single-use pa-

per towels or an air dryer.

Result: Hands are now sanitized and ready for work in the hygienic zone. Crucially, they were washed after boot cleaning, minimizing the

risk of re-contamination from boot-splash during washing.

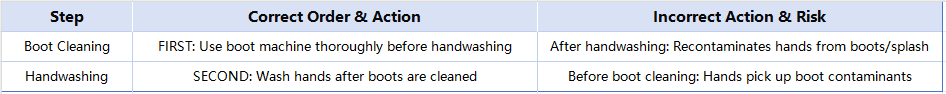

DO THIS, NOT THAT:

The Consequences of Getting it Wrong

Reversing this sequence undermines the entire hygiene process:

Product Contamination: Pathogens (like Salmonella, Listeria, E. coli) from the external environment can be introduced directly to meat or

seafood via contaminated hands or boots.

Surface Contamination: Equipment, conveyor belts, and work surfaces become vectors for spreading pathogens.

Foodborne Illness Outbreaks: The ultimate, devastating consequence, leading to human illness, product recalls, brand damage, regulatory

action, and potential plant closures.

Failed Audits: Strict adherence to documented hygiene protocols, including sequence, is a key requirement for food safety certifications

(SQF, BRC, etc.).

Compliance is Collective Responsibility

Management must provide:

- Clearly marked, well-maintained boot cleaning machines at all entry points.

- Adequate, accessible, and well-stocked handwash stations (soap, water, towels).

- Continuous training emphasizing the why and how of the sequence.

Employees must:

- Understand the critical reasoning behind "Boots First, Hands Second."

- Consistently perform both steps correctly every single time they enter.

- Hold each other accountable for following the protocol.

Conclusion: It's Simple Science, Not Just Rules

"Brush Your Boots First, Then Wash Your Hands" isn't an arbitrary rule; it's a scientifically sound procedure designed to create a physical

barrier against contamination. It ensures that the primary source of external dirt (boots) is addressed before sanitizing the primary tools of

handling (hands). In the delicate ecosystem of meat and seafood processing, respecting this sequence is a non-negotiable act of professio-

nalism and a direct commitment to producing safe, wholesome food for consumers. Make it an unwavering habit every time you step into

the workshop.